Smart Warehousing with Odoo: How Automation Changed the Game

Smart warehousing has rapidly evolved from a specialized industry buzzword into a mainstream operational strategy adopted by global businesses seeking efficiency, visibility, and scalability. In a world defined by fast-moving supply chains and rising customer expectations, enterprises no longer rely on manual spreadsheets, disconnected systems, or repetitive labor-intensive processes to manage the heart of their operations. They require intelligent, integrated, and automated solutions capable of streamlining inventory management, increasing accuracy, and improving fulfillment speed. This case study explores how the implementation of Odoo-based smart warehousing solutions revolutionized warehouse operations, reduced inefficiencies, and delivered measurable business outcomes. Through real-world challenges, practical implementation insights, and proven results, the study demonstrates how automation, data intelligence, and process integration transformed the warehousing game for modern enterprises.

Introduction

Warehousing has always been the engine room of every product-based organization. Whether a company deals with manufacturing, retail, distribution, or e-commerce, the efficiency of its warehouse directly influences customer satisfaction, supply chain performance, and financial outcomes. However, traditional warehouses have long struggled with manual bottlenecks such as misplaced inventory, slow picking cycles, data discrepancies, and lack of real-time visibility. As customer expectations continue to grow and businesses expand across multiple channels, these limitations became more pronounced, creating a wave of operational challenges that demanded a digital-first transformation.

Automation emerged as the most powerful catalyst in this transformation. With the advent of smart technologies, businesses began adopting advanced warehouse management systems, robotics, IoT sensors, barcode automation, and mobile tracking mechanisms to streamline complex workflows. Amidst this evolution, Odoo stood out as a flexible and highly scalable ERP solution capable of integrating every warehouse function into a unified, intelligent platform. Its Warehouse Management System redefined how businesses handled storage optimization, order processing, replenishment, tracking, costing, quality control, and fulfillment.

This case study explores how one medium-sized multi-location distribution company transitioned from traditional warehousing practices to a fully automated smart warehouse powered by Odoo. It delves into the operational challenges faced before automation, the technologies used, the implementation timeline, and the measurable improvements achieved. The story highlights how automation reshaped productivity, minimized human errors, reduced operational costs, and created a continuous improvement cycle that transformed warehousing from a reactive function into a strategic growth driver. Through a structured narrative and data-backed insights, the study demonstrates why Odoo-enabled smart warehousing has become a game changer in modern supply chain management.

What is Smart Warehousing ?

Smart warehousing refers to the use of advanced digital technologies, automation tools, integrated software systems, and intelligent data-driven processes to optimize warehouse operations. Unlike traditional manual warehouses where most activities depend on human judgment and repetitive manual tasks, smart warehouses leverage technology to automate inventory tracking, order fulfillment, replenishment, and workflow coordination. The emphasis lies in precision, speed, transparency, and scalability, making the warehouse capable of adapting dynamically to demand fluctuations and operational complexities.

Smart warehousing introduces several key components such as real-time inventory visibility through barcode scanning and RFID tags, automated picking and packing through handheld devices, cross-docking systems to accelerate movement, digital quality checks to eliminate defects, and predictive analytics to anticipate stock requirements. The integration of IoT sensors enables tracking environmental conditions, equipment utilization, and movement patterns, optimizing both layout planning and labor allocation. The goal is to create a self-regulating ecosystem where decisions are supported by data, processes run on standardized workflows, and human involvement focuses on analytical and supervisory roles instead of repetitive manual tasks.

Odoo’s smart warehousing capabilities extend this vision further by offering a unified platform that connects procurement, sales, manufacturing, logistics, accounting, and CRM. Every inventory movement becomes traceable from supplier to customer. Every transaction is recorded instantaneously, and every workflow is validated by automation rules. Through intelligent routing, wave picking, batch processing, and mobile scanning, Odoo transforms warehouses into agile, efficient, and data-driven environments. Smart warehousing is not merely an upgrade to existing operations; it is a strategic transformation that enhances business scalability, profitability, and customer trust.

How Smart Warehousing Works

Smart warehousing operates through a seamless combination of technologies, integrated processes, and automated decision-making systems. The first step lies in establishing an interconnected digital ecosystem. Barcodes, RFID tags, and IoT sensors track every inventory unit from entry to exit. These technologies feed real-time data into Odoo’s warehouse management platform, ensuring complete visibility into stock levels, locations, movements, and statuses. This eliminates manual entry errors and delays typically caused by disconnected systems.

When goods arrive, automated put-away rules categorize and assign storage locations based on predefined parameters such as weight, frequency of movement, shelf capacity, and pick route efficiencies. Instead of warehouse workers choosing arbitrary storage areas, the system recommends or assigns optimized locations automatically, reducing travel time and improving space utilization. Similarly, during order fulfillment, Odoo’s routing engine determines the most efficient picking method be it wave picking, zone picking, or batch picking depending on order volumes, priority, and warehouse layout. This minimizes movement and accelerates shipping speed.

Inventory replenishment is handled by automated triggers. When stock levels fall below minimum thresholds, Odoo initiates purchase orders or internal transfers automatically, preventing shortages while avoiding overstock situations. Integrated handheld devices guide workers through each workflow, from receiving to counting to packing, using step-by-step instructions and error-proof workflows. The integration with accounting ensures real-time valuation updates, costing accuracy, and financial transparency.

Smart warehousing also incorporates machine learning and predictive analytics to forecast demand, identify slow-moving items, and optimize stock rotation strategies. By analyzing historical patterns, customer behavior, and seasonal trends, businesses can anticipate inventory needs and adjust procurement strategies in advance. Quality control is integrated into every stage, enabling automated checkpoints that ensure defective or expired items are identified before shipping.

In essence, smart warehousing transforms every operational activity into a digital, trackable, and optimized process. The result is a warehouse that performs faster, adapts quicker, operates with fewer errors, and contributes significantly to overall business performance.

Technology Used

The backbone of smart warehousing lies in leveraging cutting-edge technologies that work cohesively to automate, optimize, and scale warehouse operations. Odoo’s flexible architecture supports a wide range of integrated technologies that enhance visibility, accuracy, and efficiency.

Barcode and QR Code Automation forms the foundation of inventory tracking. Every item, carton, shelf, pallet, and location is tagged with scannable codes. Workers use handheld barcode scanners or Odoo’s mobile application to track movements, confirm processes, and update records automatically, eliminating manual errors.

RFID Technology provides real-time tracking of assets without requiring line-of-sight scanning. It is especially useful for high-volume warehouses handling fast-moving goods. RFID readers and antennas automatically log item movement, reducing human intervention.

IoT Devices and Sensors enhance warehouse intelligence by monitoring temperature, humidity, machine health, and storage conditions. These sensors integrate seamlessly with Odoo to trigger alerts, automate compliance checks, and ensure product integrity especially important for food, pharma, and perishable goods.

Odoo ERP Integration is the core technology that binds every warehouse function together. The Warehouse Management System connects with procurement, sales, manufacturing, POS, e-commerce, finance, and CRM to create a unified operational ecosystem. Data flows seamlessly across modules, enabling transparency and synchronization.

Mobile Warehousing Tools enable workers to perform picking, packing, put-away, and counting tasks through smartphones or rugged industrial tablets. The mobile interface is designed to guide workflows clearly, eliminating dependency on paperwork or desktop systems.

Machine Learning and Predictive Analytics support forecasting, replenishment planning, and optimization of storage layouts. These technologies identify patterns in sales, movement cycles, and seasonal demand to recommend data-driven strategies.

Robotics and Automation Tools integrate with Odoo through APIs, allowing automated guided vehicles, conveyor systems, and robotic arms to take over repetitive picking or sorting tasks. Smart warehouses often use hybrid automation where human workers and robots collaborate in real-time.

Cloud Infrastructure ensures accessibility, scalability, and security. Odoo’s cloud-based deployment allows multiple warehouse locations to operate under a centralized system, ensuring consistent performance and unified reporting.

Together, these technologies form the digital foundation of smart warehousing, enabling businesses to maintain accuracy, boost productivity, and scale their operations seamlessly.

Challenges

Before adopting smart warehousing powered by Odoo, the company faced significant operational challenges that impeded efficiency, performance, and profitability. The warehouse relied heavily on manual operations, leading to frequent delays, inaccuracies, and inefficiencies.

Inventory mismatch was one of the most critical issues. Stock levels recorded on spreadsheets rarely matched physically available quantities, resulting in stockouts, over-purchasing, and customer dissatisfaction. Manual counting methods consumed significant labor hours, yet discrepancies remained high.

Order fulfillment delays were frequent due to unoptimized picking routes. Workers often spent excessive time locating items because storage was not systematically organized. Without automated location tracking, misplaced inventory became a recurring problem, further slowing operations.

The absence of real-time visibility created communication gaps between departments. Sales teams frequently committed to deliveries without knowing actual stock availability. Procurement teams often reacted late to shortages, leading to urgent purchases at higher costs. The warehouse worked in isolation, creating a fragmented supply chain.

Quality control issues emerged due to lack of automated checks. Expired, damaged, or incorrect items occasionally reached customers, affecting brand reputation and increasing return rates.

Labor inefficiency became a growing concern as the business scaled. Repetitive manual tasks increased workload and fatigue, leading to more errors. Training new workers was time-consuming due to lack of standardized digital workflows.

Multi-warehouse management posed further complications. Each location followed its own manual system, producing inconsistent processes and unreliable reports. Transfer orders were often delayed, misrouted, or poorly documented.

The business struggled to maintain accurate costing, valuation, and audit trails. The finance team frequently reconciled discrepancies, adding additional workload and delaying financial reporting.

These challenges highlighted the urgent need for a unified digital platform that could automate operations, ensure accuracy, enhance visibility, and prepare the business for scalable growth.

Solution with Odoo Smart Warehousing

To address these operational challenges, the company implemented Odoo’s smart warehousing solution, transforming its entire warehouse infrastructure into an automated, technology-driven ecosystem. The solution focused on eliminating manual errors, streamlining internal workflows, and providing real-time visibility across all warehouse functions.

Odoo introduced automated inventory tracking through barcode and mobile scanning, ensuring every movement was recorded instantly and accurately. Put-away rules automated the storage process, assigning optimal locations based on product characteristics, movement frequency, and shelf capacity. This significantly reduced search time and improved space utilization.

Real-time stock tracking eliminated discrepancies by synchronizing physical movements with system updates. Each picking, packing, transfer, or adjustment was validated through scanner devices, ensuring hundred percent accuracy.

The order fulfillment process was redesigned using intelligent routing methods such as wave picking and batch picking. Workers received digital instructions on handheld devices, guiding them through the most efficient pick paths. This increased picking speed and reduced fulfillment time.

Automated replenishment rules ensured no item reached critical shortage levels. Minimum and maximum thresholds for each product triggered automatic purchase orders or internal transfers. This reduced urgent buying and stabilized inventory flow.

Quality control checkpoints were embedded into workflows. Scanning errors, mismatched quantities, or damaged goods automatically triggered quality alerts, preventing defective products from moving forward.

Multi-warehouse operations were centralized in Odoo, creating a unified digital interface for all locations. Managers could monitor stock in real-time, transfer items digitally, and maintain standardized processes across facilities.

Integration with sales, procurement, accounting, and manufacturing created end-to-end traceability. Every item could be tracked from supplier to customer, improving transparency and enabling data-driven planning.

The solution established a streamlined, automated, and scalable warehouse environment capable of supporting rapid growth while maintaining operational excellence.

Implementation Journey

The implementation of Odoo smart warehousing followed a structured, multi-phase journey designed to ensure seamless transition, minimum disruption, and maximum adoption.

The discovery and analysis phase began with a detailed assessment of existing warehouse workflows. This involved shadowing workers, mapping inventory movements, documenting bottlenecks, analyzing error patterns, and reviewing layout inefficiencies. Business requirements were consolidated to design a custom roadmap tailored to the company’s operational realities.

The system design phase involved configuring Odoo’s Warehouse Management System to align with business-specific processes. This included defining product categories, storage locations, picking strategies, replenishment rules, and quality control checkpoints. The integration architecture was planned for connecting the warehouse with sales, procurement, accounting, and manufacturing.

The data migration phase ensured all product data, historical records, vendor lists, customer data, and valuation details were transferred into Odoo. Legacy records were cleaned and standardized to ensure consistency.

The infrastructure setup introduced barcode scanners, handheld devices, IoT sensors, and network enhancements required for smart warehousing. Each device was configured to communicate seamlessly with Odoo.

The training and change management phase played a critical role in user adoption. Workers were trained on mobile workflows, scanning methods, and system navigation. Training simulations recreated real warehouse tasks to ensure comfort and confidence.

The testing and pilot run phase validated every workflow in a controlled environment. Pilot runs were executed in a single zone before expanding to the entire warehouse. Bugs were resolved, workflows optimized, and user feedback incorporated.

The go-live phase transitioned the warehouse into fully automated operations. Support teams remained onsite to ensure real-time troubleshooting and user assistance.

The post-implementation optimization phase analyzed system performance, fine-tuned automation rules, and identified opportunities for deeper integration or advanced analytics.

This methodical journey ensured a smooth transformation from manual warehousing to a fully automated smart warehouse powered by Odoo.

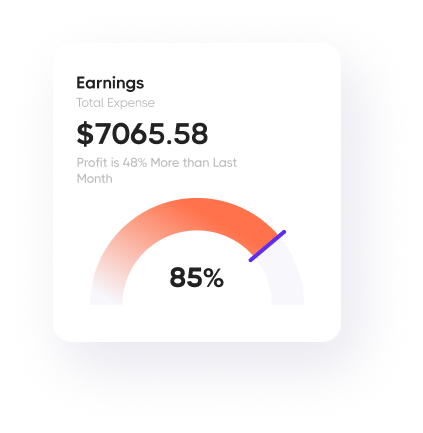

Impact of Smart Warehousing

The impact of implementing Odoo-based smart warehousing was transformative and measurable across every operational dimension. One of the most significant outcomes was the drastic reduction in inventory inaccuracies. Stock mismatch dropped from an average of 18 percent discrepancy to less than 1 percent within the first three months. Real-time stock visibility enabled accurate planning, ensured timely replenishment, and improved supplier coordination.

Order fulfillment efficiency improved remarkably. Picking speed increased by 45 percent due to optimized routes and mobile scanning. The average order processing time decreased by 38 percent, enabling faster deliveries and enhancing customer satisfaction.

Stockouts reduced by 60 percent owing to automated replenishment rules and predictive insights. This stabilized product availability, improved sales continuity, and minimized emergency procurement costs.

Labor productivity improved substantially. Workers spent significantly less time on manual tasks such as searching for items, writing records, or counting inventory. Labor efficiency increased by 40 percent while errors dropped drastically due to standardized digital workflows.

Return rates attributable to warehouse errors such as wrong item shipments fell by more than 70 percent. Quality control checkpoints played a pivotal role in ensuring accuracy and preventing defects from moving downstream.

Cost savings were realized across multiple areas. Reduced errors, optimized storage, faster fulfillment, and minimized shortages contributed to a 25 percent reduction in operational costs within the first year.

Multi-warehouse visibility strengthened cross-location planning. Managers could redistribute stock efficiently, preventing overstock and understock situations. Centralized reporting simplified audits and improved financial transparency.

Overall business scalability improved dramatically. The warehouse was now capable of handling increasing order volumes without proportional increases in manpower or costs. Automation enabled operational resilience, allowing the company to grow rapidly while maintaining efficiency.

Benefits of Automation with Odoo

The transition to smart warehousing delivered numerous benefits that extended beyond operational improvements. One major benefit was enhanced decision-making. Real-time insights into stock levels, movement patterns, and fulfillment performance empowered managers to make data-driven decisions, strengthen planning cycles, and reduce uncertainties.

Customer satisfaction soared due to faster deliveries, improved accuracy, and consistent product availability. The business recorded a noticeable increase in repeat orders and customer loyalty. Fulfillment reliability strengthened the company’s brand reputation and competitive edge.

The standardized workflows simplified compliance, audits, and traceability. Every transaction was recorded digitally, enabling end-to-end tracking and seamless reporting. The system supported inventory costing methods, financial accounting, and audit trails with unmatched accuracy.

Employees benefited from reduced workload, safer workflows, and intuitive digital tools. Automation eliminated fatigue from repetitive tasks, allowing workers to focus on value-added activities. The modern digital environment improved overall job satisfaction.

The business gained scalability without proportional cost increases. The warehouse could now handle higher order volumes, peak seasons, and multi-channel operations effortlessly. Automation offered long-term sustainability, reduced operational risk, and strengthened profitability.

Future Outlook

The future of smart warehousing with Odoo lies in deeper automation, AI-driven decision-making, robotics integration, and predictive logistics. As businesses face increasing supply chain complexities, the demand for autonomous and self-optimizing warehouses will grow rapidly.

Odoo’s platform is evolving to incorporate machine learning algorithms for demand forecasting, autonomous replenishment, and intelligent route optimization. Robotics integration will enable automated picking, sorting, and material movement. IoT expansion will enhance predictive maintenance, environmental monitoring, and equipment optimization.

The shift toward omni-channel commerce will require dynamic fulfillment strategies, integrating e-commerce, retail, and B2B operations seamlessly through Odoo’s unified system.

Digital twins and warehouse simulations will allow businesses to test layout changes, workflow enhancements, and growth strategies digitally before executing them in real life.

Blockchain integration may further strengthen traceability, compliance, and product integrity. The future warehouse will be fully autonomous, highly connected, and capable of continuous adaptation.

Conclusion

The transformation to smart warehousing using Odoo marks a fundamental turning point for modern businesses. The integration of automation, intelligent workflows, and real-time visibility reshaped the company’s entire operational foundation, enabling accuracy, speed, and scalability that manual processes could never achieve. Through structured implementation, technological innovation, and data-driven strategies, the warehouse transitioned from a traditional storage facility into a high-performing strategic asset.

The measurable outcomes from reduced errors to improved fulfillment speed and cost savings demonstrate the powerful impact of Odoo’s smart warehousing capabilities. Beyond operational efficiency, the transformation strengthened customer satisfaction, improved worker experience, enhanced financial transparency, and prepared the business for long-term scalability.

Smart warehousing is no longer an optional upgrade. It is an essential competitive advantage in the digital age. Companies that embrace advanced warehouse automation through platforms like Odoo will continue to outperform competitors, adapt faster to market shifts, and deliver exceptional value to customers. This case study highlights not just the success of one implementation but the immense potential of Odoo smart warehousing in transforming the future of global supply chains.

Our Clients Recognize Us as the Leading Odoo Development Experts.

We transform your business vision into success using advanced Odoo solutions, creativity, and accuracy, making us the preferred partner for global enterprises.