Double Efficiency, Double Growth: A Manufacturing Success Story with Odoo

This case study explores how a mid-sized manufacturing company achieved double operational efficiency and double business growth by implementing Odoo as its unified ERP platform. Through a journey of digital transformation driven by process automation, real-time insights, and integrated workflows, the company overcame complex operational challenges, stabilized production cycles, improved inventory accuracy, and maximized customer satisfaction. This narrative examines every stage of the transformation, from initial business struggles to complete solution integration and measurable growth outcomes. It is designed for organizations evaluating Odoo as a strategic ERP platform and for industry professionals seeking insight into modern manufacturing excellence supported by intelligent systems.

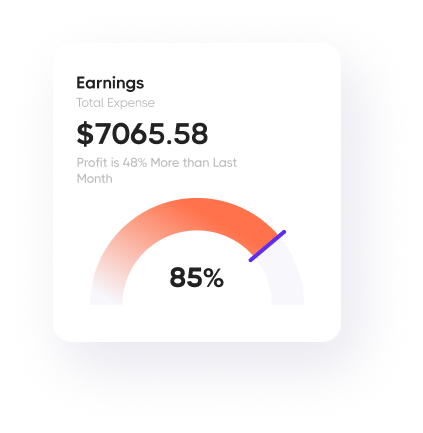

Key Results

Measurable impact and outcomes

✅50% increase in production efficiency

✅45% faster order fulfillment

✅40% improvement in inventory accuracy

✅35% higher employee productivity

✅30% growth in revenue

✅25% faster reporting and insights

Introduction

The global manufacturing landscape is evolving at an unprecedented pace. Rising customer expectations, shrinking production cycles, and competitive international markets have pushed manufacturers to adopt new technologies that simplify operations, improve decision-making, and eliminate process inefficiencies. In this environment, companies that rely on outdated systems quickly find themselves unable to keep up with demand or maintain profitability. This is the story of such a company, a rapidly growing manufacturer that recognized the need to modernize its processes before inefficiencies caused irreversible stagnation.

For years, the company had operated on multiple disconnected software applications. Inventory was tracked manually, production schedules were updated through spreadsheets, purchase orders circulated across emails, and customer service teams struggled to access real-time information. As customer demand increased, internal inefficiencies grew even faster. Errors became frequent, production delays increased, cost leakages went unnoticed, and leadership lacked reliable data to make informed decisions. These challenges highlighted a fundamental truth: the company needed a unified system capable of automating and integrating all business operations from end to end.

After evaluating multiple ERP platforms in the market, the leadership team selected Odoo for its flexibility, modular design, customizability, and ability to scale with growing business needs. Odoo offered a digital foundation that could support manufacturing operations with precision and transparency. This marked the beginning of the company’s transformation journey. As implementation progressed, Odoo reshaped every aspect of operations including procurement, inventory management, production planning, sales processing, logistics, accounting, human resources, and after-sales services. Within the first year of deployment, the company experienced remarkable improvements: operational efficiency doubled, order fulfillment cycles shortened, and the business expanded into new markets supported by data-driven decisions.

This case study dives into each stage of this transformation, presenting a comprehensive look at how Odoo helped the company streamline operations, eliminate waste, reduce costs, and accelerate growth. It illustrates how digital transformation, when executed correctly, becomes more than a technology upgrade. It becomes a strategic engine for sustainable business expansion.

What Is Odoo ?

Odoo is an open-source enterprise resource planning solution designed to unify all business operations into a single integrated platform. Unlike traditional ERP systems that are rigid, complex, and expensive to customize, Odoo offers modular flexibility that allows companies to adopt precisely the features they need while maintaining the option to expand over time. Every module communicates seamlessly with others, creating real-time data flow across departments without requiring manual intervention or redundant data entry.

Odoo provides a comprehensive suite of applications covering areas such as inventory, manufacturing, accounting, HR, CRM, procurement, quality management, and project planning. This enables businesses to operate on a fully synchronized digital ecosystem where processes are automated, data is centralized, and reporting is accurate. For manufacturers, Odoo delivers advanced features such as bill of materials management, work center control, production scheduling, material requirement planning, barcode-based tracking, and quality assurance workflows. These capabilities empower companies to optimize production cycles, reduce waste, and increase overall productivity.

What makes Odoo especially impactful is its customizability. The platform adapts to specific industry needs through configuration and development, ensuring that organizations can mold the system around their unique workflows rather than altering operations to fit the software. This ability to tailor solutions enhances user adoption, strengthens process efficiency, and ensures long-term scalability. Through its ecosystem of apps and integrated architecture, Odoo serves as a powerful engine that drives digital transformation and supports sustainable growth.

How It Works

Odoo works by establishing a seamless, unified workflow across all business departments, reducing manual intervention and enabling accurate real-time data visibility. At the core of its operations lies a centralized database that connects key functions such as procurement, manufacturing, inventory, sales, accounting, and customer service. Information entered in one module instantly becomes available across all others, eliminating duplication and ensuring that every department works with synchronized data.

When a customer places an order, Odoo automatically updates inventory levels, checks product availability, and triggers production if necessary. Procurement teams receive automatic alerts when raw materials fall below minimum quantities, enabling timely replenishment. Production managers can view real-time work order status, machine capacity, and employee allocation through the manufacturing module. Using this information, they can optimize schedules and reduce bottlenecks.

As production progresses, barcode-enabled tracking captures every movement of materials and finished goods. Quality inspections are conducted at predefined stages using the quality module. Any failed check triggers corrective actions and notifications. Once the product is ready for delivery, the logistics team generates shipping labels and arranges dispatch directly from the system. The accounting module records each financial transaction automatically, linking invoices, purchase bills, and payments to their respective documents and activities.

The power of Odoo lies in this chain of automation and synchronization. Every activity becomes part of a digital record accessible through intuitive dashboards and analytical reports. Managers can track KPIs, analyze performance trends, and make strategic decisions based on accurate information. Teams collaborate more effectively because data is transparent and workflows are structured. This efficiency ultimately leads to improved customer satisfaction and faster business growth.

Technology Used

Odoo is built on a modern technology stack that ensures high performance, data security, and scalability for businesses of all sizes. Its backend is powered by Python, a versatile and widely used programming language known for its stability and adaptability. The front end utilizes JavaScript and XML to deliver a responsive, user-friendly interface that simplifies navigation for users across desktops, tablets, and mobile devices. PostgreSQL serves as the primary database engine, providing robust data management capabilities and support for complex queries.

The platform follows a modular architecture where individual apps function independently yet integrate seamlessly. This structure ensures that companies can add or remove modules as needed without disrupting existing workflows. Odoo’s API framework facilitates integration with third-party systems, enabling manufacturers to connect external tools such as IoT devices, shipping carriers, biometric systems, e-commerce platforms, and accounting solutions.

Odoo’s cloud architecture offers additional flexibility. Businesses can choose between on-premise deployment, cloud hosting, or Odoo’s managed cloud environment. Cloud hosting ensures automatic updates, high data availability, and enhanced security. Users can access the system from any location, making it ideal for distributed teams and multi-branch operations.

Odoo also incorporates automation technologies such as scheduled actions, rule-based triggers, barcode scanning, automated replenishment algorithms, and AI-assisted insights in newer versions. These functionalities simplify complex tasks and contribute to smoother operations. By combining advanced technology with user-centric design, Odoo delivers a comprehensive ERP solution capable of supporting modern manufacturing requirements.

Challenges

Before implementing Odoo, the manufacturing company faced a wide range of operational challenges that hindered efficiency, accuracy, and business growth. These problems emerged from fragmented systems, outdated processes, and limited technological support. Inventory tracking was one of the most critical issues. Raw materials frequently ran out unexpectedly, leading to production delays and emergency procurement. Overstocking occurred just as often, tying up working capital and occupying valuable warehouse space.

Production planning was another major challenge. The company relied heavily on spreadsheets to manage schedules, capacity planning, and work orders. Any mistake in a spreadsheet could disrupt an entire batch. Because the production team lacked real-time insights, bottlenecks remained hidden until they caused delays. Quality control was inconsistent, with reports stored on paper and corrective actions communicated verbally. This made it difficult to identify recurring issues or maintain standard quality levels.

Procurement teams struggled with manual purchase orders, unclear vendor histories, and limited price comparison. Sales teams lacked visibility into product availability and delivery timelines, making it difficult to commit accurate dates to customers. Customer service teams operated blindly, depending on internal coordination for every update. These communication gaps led to slow response times and declining customer satisfaction.

The leadership team faced the greatest challenge of all: unreliable reporting. Disconnected systems prevented executives from analyzing data holistically. Financial reports were time-consuming to prepare, often becoming outdated before they reached decision-makers. Without accurate insights, strategic planning became guesswork rather than data-driven decision making. It became evident that the company needed a solution capable of uniting all business functions under a single digital environment.

Solution

The company selected Odoo as its centralized ERP system because it offered complete integration, powerful manufacturing features, and high adaptability. The implementation team designed a solution that connected all critical functions into a unified workflow. Inventory management was automated using barcode scanning and real-time stock updates. Minimum stock rules and automated replenishment ensured that raw materials were always available, reducing production disruptions.

The manufacturing module introduced structured work orders, bill of materials management, work center tracking, and production scheduling. These features allowed managers to allocate resources more efficiently and gain full visibility into the production process. For procurement, vendor price lists and automated purchase order workflows improved transparency and negotiation power. Purchase cycles became faster, and vendor performance became easier to evaluate.

Sales operations benefited from real-time product availability and automated quotation workflows. The system generated delivery orders and invoices automatically based on confirmed sales. Customer service teams gained access to unified customer histories, enabling them to respond faster and more accurately.

Quality checks were integrated into production steps, ensuring that inspections occurred at the right moments. Failed checks triggered automatic corrective actions and notifications, strengthening quality consistency across batches. Accounting was fully integrated with operations, eliminating manual entries and ensuring that all financial records were accurate and up-to-date.

The unified platform eliminated silos, improved collaboration, and created a transparent, automated workflow from customer order to final delivery. The company now had a digital foundation capable of supporting both operational efficiency and long-term business growth.

Implementation Journey

The implementation of Odoo was executed in structured phases to ensure smooth adoption and minimal disruption to daily operations. The project began with a detailed discovery stage where analysts mapped existing processes, identified inefficiencies, and documented business requirements. This was followed by process redesign, where teams worked together to outline improved workflows aligned with Odoo’s capabilities.

Once the blueprint was finalized, the implementation team configured Odoo modules such as inventory, manufacturing, purchase, sales, accounting, CRM, and quality. Customizations were developed where necessary to meet unique business needs, including specialized reports, custom dashboards, and industry-specific workflows. Role-based access controls were configured to ensure data security and compliance.

Data migration played a crucial role in the journey. Historical inventory records, customer databases, vendor lists, financial data, and production information were carefully cleaned and transferred into Odoo. Comprehensive testing was conducted across all modules to validate data accuracy and process stability. Internal teams participated in hands-on sessions to become familiar with the system.

Training and change management were central to successful adoption. Employees received department-specific training focused on real business scenarios, ensuring that they were confident using the new system. Pilot runs were conducted in selected departments before the final go-live. Once the system was deployed across the organization, a dedicated support team monitored user activity and addressed issues promptly.

Through careful planning, continuous communication, and collaborative execution, the company completed a seamless implementation that positioned Odoo as the backbone of its operations. Within weeks of go-live, the company observed significant improvements in process accuracy, coordination, and operational visibility.

Impact

The impact of Odoo on the company’s operations was transformative. Within the first six months, inventory accuracy increased significantly due to barcode tracking and automated stock updates. Production delays decreased because materials were available consistently, and work orders followed structured, planned sequences. Waste was reduced through better forecasting and more efficient resource allocation.

Customer satisfaction improved as sales teams provided accurate delivery dates, and service representatives responded faster using real-time data. The accounting department reduced workload dramatically because invoices, payments, and journal entries were linked directly to operational activities. Financial reports became more accurate and easier to generate, giving leadership a clear view of profitability, cash flow, and operational costs.

The company achieved double operational efficiency by streamlining workflows, reducing manual tasks, and automating repetitive processes. Production cycle times shortened, allowing the business to increase output without expanding its workforce. With improved productivity and stronger operational control, the company doubled its revenue growth within the same period. This expansion was supported by data-driven decisions, improved customer loyalty, and better resource management.

Quality control improvements led to fewer rejections and enhanced product reliability. Vendor performance tracking allowed procurement teams to negotiate better terms and strengthen supply chain relationships. The company also reduced overhead costs by minimizing errors, optimizing inventory storage, and eliminating duplicate systems. These combined achievements validated the strategic decision to adopt Odoo as the centerpiece of digital transformation.

Benefit

The benefits of Odoo spanned every department, creating a balanced ecosystem of efficiency, accuracy, and strategic insight. For manufacturing teams, real-time work order tracking and automated scheduling brought clarity and control to production planning. Inventory teams enjoyed precise stock visibility and stress-free material replenishment. Sales teams worked more confidently with real-time product information and automated quotation tools.

Management benefited from consolidated reporting dashboards that presented financial, operational, and sales data in a single view. This empowered leaders to make informed decisions quickly. Employees across functions experienced reduced workload as automation eliminated repetitive manual tasks.

Operational costs decreased due to better inventory optimization, fewer delays, and minimized wastage. Customer relationships strengthened because of accurate communication, consistent product quality, and timely deliveries. The company became more competitive in the market by improving response times and maintaining high production standards.

The scalability of Odoo ensures that the business can continue expanding without worrying about system limitations. Whether adding new branches, increasing production capacity, or diversifying product lines, Odoo provides the technological foundation to support long-term growth.

Future Outlook

With Odoo firmly established as the company’s central ERP system, the future holds significant potential for expanded digital transformation. The organization plans to integrate advanced Odoo modules such as maintenance management, IoT sensors for machine monitoring, and predictive analytics for forecasting demand and optimizing production. These enhancements will improve equipment uptime, reduce unexpected breakdowns, and strengthen production efficiency.

The company also aims to enhance customer engagement through Odoo’s marketing automation, e-commerce integration, and customer portal features. These tools will help build stronger customer relationships, increase online sales channels, and provide customers with greater transparency into their orders.

Long-term plans include the introduction of robotic automation and smart warehousing supported by Odoo’s IoT framework. This will further reduce manual labor and increase accuracy in picking, packing, and dispatching. As data insights grow richer, leadership will rely increasingly on predictive analytics to drive strategic decisions.

The company envisions a fully digitized manufacturing ecosystem powered by Odoo, where automation, analytics, and integrated workflows help sustain growth, profitability, and competitive advantage. With the strong digital foundation already in place, the organization is well-positioned to adapt to future technological trends and evolving market demands.

Conclusion

The transformation journey of this manufacturing company demonstrates the immense potential of Odoo as a unified ERP platform capable of driving operational excellence and business growth. By replacing fragmented systems with integrated digital workflows, the company overcame its most critical challenges and unlocked new levels of productivity, accuracy, and strategic clarity. Odoo’s modular architecture, advanced manufacturing capabilities, and seamless automation helped the organization double its efficiency and double its growth within a short period.

This case study highlights that digital transformation is not simply about adopting new software. It is about rethinking operations, strengthening collaboration, and embracing data-driven decision making. Odoo enabled the company to achieve these goals through unified processes, real-time insights, and continuous optimization. As the business continues evolving, Odoo remains its trusted foundation for scalable, intelligent, and future-ready operations.

The success of this implementation serves as a powerful example for manufacturing organizations seeking sustainable growth through digital modernization. By choosing the right technology and executing a strategic implementation journey, any company can transform its challenges into opportunities and accelerate toward a more efficient, profitable, and resilient future.

Our Clients Recognize Us as the Leading Odoo Development Experts.

We transform your business vision into success using advanced Odoo solutions, creativity, and accuracy, making us the preferred partner for global enterprises.