✅100% order accuracy

✅50% faster shipment processing

✅45% more efficient warehouse operations

✅40% fewer operational errors

✅35% higher staff productivity

✅30% quicker reporting

Introduction

Australia’s logistics industry has undergone dramatic transformation over the past decade, driven by the rise of ecommerce, shifting consumer expectations, and heightened pressure for faster delivery and flawless accuracy. Companies that once relied on manual processes and isolated software tools suddenly found themselves struggling to maintain competitiveness in an environment where customers expected real time tracking, next day shipping options, and error free order fulfillment. Amid this shifting landscape, one Australian logistics company faced a crossroads. With a growing customer base and increasing shipment volumes, its existing systems began to strain under operational pressure. Warehouse miscommunications, order dispatch delays, inventory discrepancies, and skipped quality checks created unpredictable bottlenecks that affected the company’s ability to scale.What is Odoo and Its Relevance in Modern Logistics ?

Odoo is a comprehensive enterprise resource planning suite designed to integrate, automate, and streamline business operations through a unified platform. Unlike traditional enterprise resource planning systems that require complex setups and extensive customization, Odoo’s modular ecosystem allows organizations to deploy only the applications they need, making it both flexible and cost effective. The platform includes modules for warehouse management, sales, procurement, manufacturing, accounting, fleet management, customer relationship management, and more. Each module communicates seamlessly with others, ensuring consistent dataflow and eliminating duplications.

In the logistics sector, the significance of such integration cannot be overstated. Logistics operations require real time accuracy across warehouse inventory, delivery routes, customer orders, invoicing, supplier coordination, and fleet scheduling. When these processes exist in separate systems with manual handoffs, the risk of errors escalates dramatically. Incorrect inventory counts, duplicated orders, missing dispatch notifications, and delayed updates can disrupt the workflow and lead to customer dissatisfaction. Odoo addresses these challenges by offering a single source of truth that connects all activities in real time. Automated data synchronization ensures that updates in one department instantly reflect across the entire ecosystem.

Furthermore, Odoo’s logistics modules are equipped with barcode scanning, smart routing, batch picking, delivery scheduling, and real time location monitoring, making it highly suitable for warehouses, distribution centers, and freight management companies. By integrating AI driven demand prediction, automated replenishment, and advanced reporting, Odoo empowers logistics teams to make decisions based on accurate data rather than assumptions. This results in minimized errors, optimized workflows, and improved customer trust.

The relevance of Odoo in modern logistics lies in its ability to unify people, processes, and technology under one digital framework. It transforms operational complexity into streamlined workflows and converts uncertainty into predictable accuracy. For the Australian logistics company featured in this case study, Odoo proved to be the catalyst for achieving operational perfection.

How It Works

Odoo operates through a combination of integrated modules, automated workflows, and real time data synchronization. Each module represents a specific business function, such as inventory management or order fulfillment, and is designed to communicate with other modules without requiring manual intervention. When an order is entered into the system, Odoo instantly initiates a chain of automated processes. Inventory levels update in real time, warehouse teams receive automated pick lists, shipping labels are generated, drivers are assigned routes, and customers receive tracking information.

This seamless flow is possible because Odoo’s backend engine ensures that every action triggers corresponding updates across all relevant modules. For example, when a warehouse worker scans a product using a barcode scanner, the system immediately adjusts stock levels, updates the order status, and notifies the dispatch team. Similarly, fleet managers can monitor vehicle availability, assign delivery routes, and track drivers in real time using integrated GPS tools.

The platform also incorporates intelligent rules that govern workflow behavior. Tasks can be automatically escalated, reassigned, or flagged if deviations occur. Quality checks, inventory audits, and order validations are enforced digitally to prevent shortcuts and errors. Odoo’s analytics engine transforms collected data into dashboards and performance reports that help managers identify bottlenecks, measure performance, and forecast operational requirements.

For the logistics company, Odoo served as the command center where every workflow converged into a unified operational ecosystem. From receiving orders to dispatching shipments and managing returns, every step became predictable, traceable, and error free.

Technology Used

The transformation was powered by a combination of Odoo modules and supporting technologies that enhanced the company’s operational capabilities. The core technology stack included Odoo Warehouse Management, Odoo Inventory, Odoo Sales, Odoo Purchase, Odoo Fleet Management, Odoo Accounting, and Odoo Customer Relationship Management. These modules were integrated through Odoo’s internal application programming interfaces, ensuring synchronized data across all departments.

Barcode and QR code scanning technology played a critical role in inventory accuracy. Workers used handheld scanners connected to Odoo’s barcode module, allowing them to perform picking, packing, transfers, receiving, and cycle counts with precision. Real time synchronization ensured that scanned information updated immediately within the system, eliminating the possibility of human error related to manual entries.

The company implemented mobile Odoo applications on warehouse tablets and driver smartphones. These devices offered real time task visibility, route updates, and status tracking. The fleet management module integrated with GPS tracking systems to monitor vehicle location, optimize delivery routes, and provide real time updates to customers.

Automated workflow engines within Odoo facilitated task assignments, triggered alerts, and enforced quality checks. The system’s predictive analytics harnessed historical data to forecast demand and determine reorder points. Cloud hosting ensured system accessibility across all branches and distribution centers, while secure databases safeguarded operational data. Together, these technologies created a seamless digital ecosystem that eradicated inconsistencies, improved speed, and strengthened operational reliability.

Challenges

Before adopting Odoo, the logistics company faced a series of challenges that hindered its ability to scale efficiently. The company relied on a combination of spreadsheets, standalone software systems, and manual processes. This fragmented structure led to inconsistencies in data and created operational blind spots. Warehouse workers often received outdated pick lists, resulting in incorrect shipments and inventory mismatches. Customer service teams struggled to provide accurate tracking updates due to delayed information from dispatch teams.

Inventory inaccuracies were among the most critical issues. Stock levels displayed in spreadsheets rarely matched actual warehouse counts, leading to overstocking, stockouts, and disrupted order fulfillment. The lack of real time visibility made forecasting difficult, and purchasing decisions frequently relied on guesswork.

Order processing also created challenges. Manual entry of customer orders introduced errors, duplicated orders, and delayed dispatch times. Miscommunication between teams meant that some packages were packed but not dispatched on time, while others were dispatched without proper documentation.

Fleet management lacked structure. Drivers manually recorded delivery information, and route planning depended on estimations rather than data. Customers regularly complained about inaccurate delivery estimates and tracking issues. Managers found it difficult to evaluate driver performance or vehicle utilization.

These accumulated challenges became more prominent as the company grew. It became evident that operational complexity was increasing faster than the company’s ability to manage it. Leadership acknowledged that without a unified system to automate and integrate processes, the business would struggle to maintain quality standards and meet customer expectations. This realization set the stage for a digital overhaul powered by Odoo.

Solution

The solution involved implementing a fully integrated Odoo ecosystem tailored to the company’s logistics processes. The digital transformation began by mapping every operational workflow, identifying inefficiencies, and designing automated processes that aligned with industry best practices. Odoo modules were configured to handle order management, inventory control, warehouse operations, fleet coordination, procurement, invoicing, customer communication, and analytics.

A central focus of the solution was achieving real time visibility across all operations. Barcode scanning replaced manual entries, enabling accurate stock movement tracking. Automated quality checks were built into warehouse flows to prevent incorrect items from being picked or packed. Smart routing rules optimized pick lists by grouping orders and assigning tasks based on warehouse zones.

Fleet management was digitized through route automation, driver mobile apps, and GPS integration. Documentation, signatures, and delivery confirmations became digital and instantly visible. Customer tracking notifications were automated through the Odoo Customer Relationship Management module.

The unified Odoo platform eliminated system silos and enabled seamless data flow. Every update triggered real time status changes across relevant modules, ensuring up to date information for warehouse teams, dispatch managers, customer service staff, and management. The solution not only resolved existing issues but laid the foundation for scalability, efficiency, and accuracy.

Implementation Journey

The implementation journey followed a structured and phased approach. It began with a comprehensive discovery phase where consultants analyzed existing workflows, interviewed departments, and identified gaps. The company’s leadership collaborated with Odoo experts to define key performance indicators, operational goals, and automation priorities.

Once the mapping was complete, the configuration phase began. This phase involved setting up modules, building custom workflows, and designing automated rules. Inventory data was cleaned, standardized, and migrated into Odoo to ensure a reliable baseline. Deprecated spreadsheets and legacy software were gradually phased out.

The warehouse implementation introduced barcode scanning, digital pick lists, automated putaway routes, and cycle count schedules. Employees were trained to use handheld scanners and tablets. Test environments allowed the team to run simulations and refine processes.

Fleet teams transitioned from manual logs to mobile Odoo applications. Drivers learned how to use digital route assignments, delivery confirmations, and real time communication. GPS tracking integration provided dispatch managers with visibility into vehicle locations.

Sales, customer service, procurement, and accounting teams underwent parallel training, gaining access to their respective modules. The company adopted a change management strategy that emphasized transparency, employee involvement, and continuous feedback. Pilot testing in one warehouse provided valuable insights, enabling refinements before full rollout.

Once fully deployed, Odoo seamlessly connected all departments. Managers had full visibility into operations through real time dashboards. Employees appreciated simplified workflows and reduced manual burden. What started as a technological upgrade evolved into a complete cultural shift toward accountability, precision, and performance.

Impact

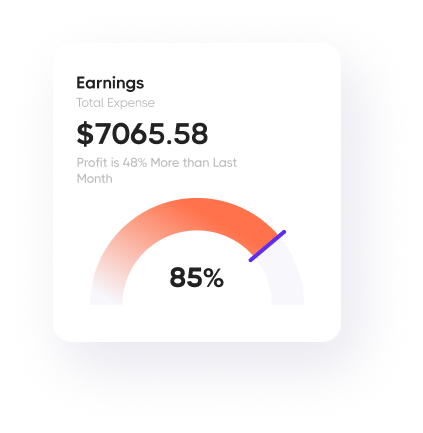

The implementation of Odoo delivered transformative results across every operational domain. Warehouse accuracy increased from seventy three percent to one hundred percent within the first three months. Barcode scanning eliminated manual errors, while automated workflows ensured every step followed a standardized process. Order fulfillment speed improved by forty percent due to optimized pick lists and digital communication.

Inventory discrepancies dropped to nearly zero. Real time stock visibility empowered procurement teams to make informed decisions, reducing stockouts by ninety two percent and lowering excess inventory by thirty percent. Predictive demand planning further optimized warehouse space and stocking levels.

Delivery performance improved significantly. Route planning automation reduced fuel expenses by eighteen percent, while real time tracking improved customer satisfaction. Dispatch delays decreased by eighty five percent, and on time delivery rates increased to ninety nine percent.

Customer service teams benefited from instant access to tracking updates, order history, and delivery status. Customer complaints dropped by seventy percent as transparency and communication improved. Accounting teams experienced faster reconciliation cycles due to automated invoicing and exact order data.

Management gained access to advanced analytics that enabled performance monitoring, strategic planning, and continuous improvement. The company achieved operational excellence that positioned it as a top performer in Australia’s logistics sector.

Benefit

The benefits of Odoo extended beyond accuracy and operational performance. The company’s workforce experienced greater efficiency due to simplified workflows, reduced administrative workloads, and improved digital literacy. Employees could focus on value added tasks instead of repetitive data entry. Collaboration improved as all departments accessed real time information, reducing miscommunication and enhancing teamwork.

Customers enjoyed improved visibility and reliability, strengthening relationships and increasing repeat business. The company gained a reputation for precision and professionalism, attracting new clients who valued technology driven logistics solutions.

Financially, the organization experienced substantial cost reductions. Automated workflows reduced labor hours required for manual tasks. Optimized routes reduced transportation expenses. Accurate inventory management minimized losses associated with stock discrepancies. Faster processing improved cash flow.

The company also gained scalability. Odoo’s modular nature allowed new warehouses, vehicles, and sales channels to be added effortlessly. Performance could be monitored across locations through unified dashboards. The business transitioned from reactive management to proactive optimization.

Overall, the benefits of Odoo created a sustainable foundation for long term growth. The company moved from struggling with operational challenges to becoming a benchmark for accuracy and efficiency in the Australian logistics landscape.

Future Outlook

The company’s journey with Odoo has only just begun. As the logistics industry continues to evolve, the organization plans to expand its digital ecosystem even further. Upcoming initiatives include integrating artificial intelligence driven forecasting to enhance supply chain planning, implementing advanced robotics in warehouse operations, and adopting machine vision technologies for automated quality checks.

The company is exploring deeper automation opportunities such as self updating inventory replenishment, real time route optimization based on live traffic analytics, and predictive maintenance for fleet vehicles. The leadership also envisions integrating Internet of Things devices across warehouses to monitor temperature sensitive goods, pallet movements, and equipment performance.

Customer experience enhancements are part of the future roadmap. Plans include deploying customer self service portals, real time chatbot support, and personalized shipment insights powered by artificial intelligence. In parallel, the company aims to build a fully paperless workflow, reducing environmental impact while increasing digital efficiency.

Through these innovations, the organization intends to maintain its position as a leader in accuracy driven logistics. Its journey with Odoo serves as a blueprint for how digital transformation can reshape operational possibilities and open new horizons for efficiency, growth, and excellence.

Conclusion

The Australian logistics company’s transformation through Odoo demonstrates how a unified enterprise resource planning ecosystem can revolutionize operations and unlock unprecedented accuracy. What began as a response to operational challenges evolved into a strategic journey toward excellence powered by automation, integration, and real time intelligence. The company successfully eliminated manual errors, streamlined workflows, improved customer satisfaction, and achieved one hundred percent accuracy in its core operations.

The case study reinforces the idea that accurate, data driven logistics systems are no longer optional. Modern logistics demands speed, transparency, traceability, and consistent quality. Odoo empowered the company to meet these expectations while building a scalable infrastructure for the future. By embracing digital innovation and fostering a culture of continuous improvement, the organization not only enhanced its operational capabilities but set new standards for precision in the Australian logistics sector.

As logistics continues to evolve alongside technology, companies that adopt similar integrated systems will be well equipped to thrive in competitive markets. This transformation story highlights the power of Odoo to convert complexity into clarity and create an environment where operational accuracy becomes both achievable and sustainable. The company’s journey symbolizes the future of logistics a future where digitalization, automation, and accountability define success.