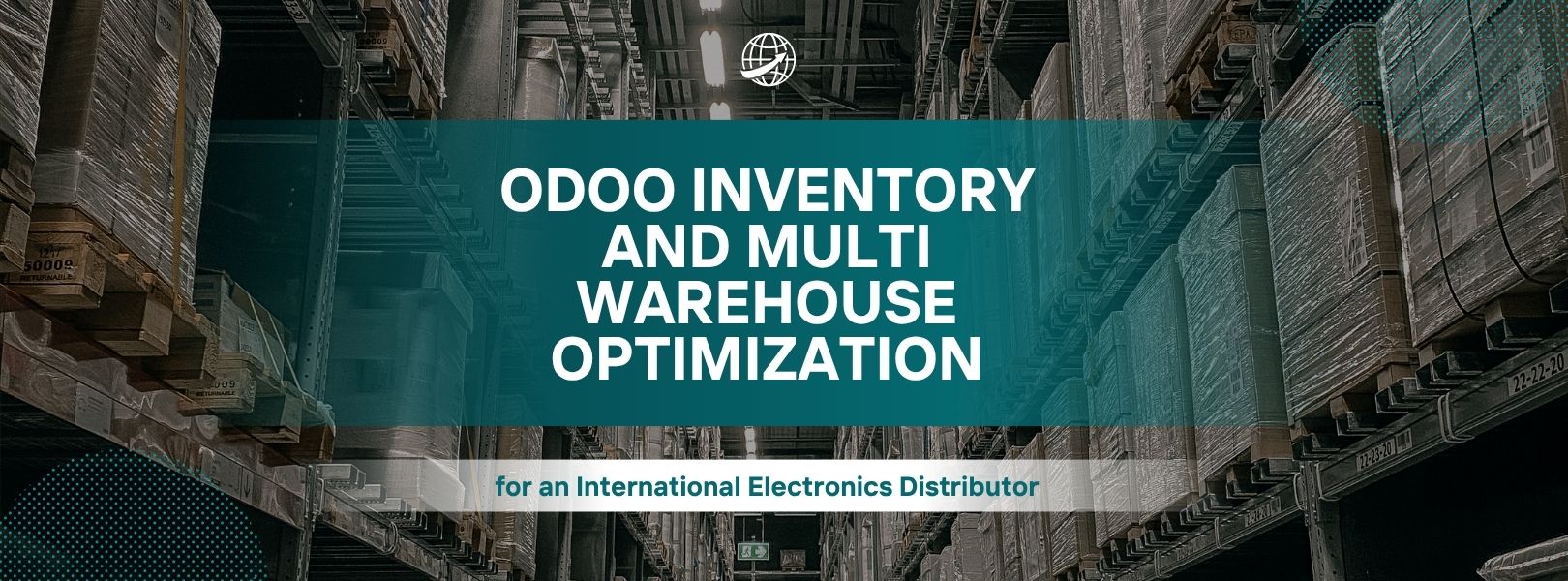

Odoo Inventory and Multi Warehouse Optimization for an International Electronics Distributor

Orbiixa carried out a detailed study of the client’s global distribution network including warehouse capacity, movement patterns, product types and region specific demand cycles. Through multiple workshops with logistics managers, procurement teams, warehouse supervisors and IT teams, we designed a scalable Odoo structure that could sustain long term expansion. Custom dashboards were created to show real time KPIs including warehouse performance, stock aging reports, product availability, reorder forecasts, fast moving and slow moving items, vendor performance and logistics cost distribution. Krazio Cloud hosting was provided to ensure high speed access for employees across all regions. Custom user roles and access levels were configured to maintain data security for different teams and regional managers. After deployment, Orbiixa delivered multi phase training to warehouse staff, procurement teams and supply chain directors ensuring smooth transition from legacy systems to a fully automated Odoo architecture.

What Client Says...

Sofia Lindberg

Global Supply Chain DirectorWorking with Orbiixa has completely transformed our warehouse operations. We finally have real time visibility, accurate data and the speed we always wanted. Our entire supply chain feels unified and far more efficient than before.

Challenge

The client was a globally active electronics distributor operating more than twelve warehouses spread across different regions including Asia, Europe and the Middle East. Their inventory handling operations involved bulk imports, regional distribution, B2B sales, retail supplies, warranty management and returns processing. However the company relied on legacy systems and spreadsheets that made real time inventory control nearly impossible. Stock mismatches occurred frequently because warehouse teams updated data manually instead of using a centralized system. Order fulfillment was often delayed due to inaccurate stock visibility and poor allocation logic between warehouses. Over stocking and under stocking both became recurring problems causing financial losses. Their supply chain managers struggled to forecast demand as trends were not tracked properly and historical data was fragmented. Inter warehouse transfers required multiple approvals but had no structured workflow which slowed down operations even further. Batch tracking and serial number assignment were also inconsistent which created complications in returns, warranties and vendor claims. The organization needed a powerful unified Odoo system capable of handling global warehouses, improving accuracy and establishing complete transparency across the supply chain.

Solution

Orbiixa delivered a fully customized Odoo Inventory and Multi Warehouse Ecosystem designed to streamline the client’s multinational supply chain. Our team built an advanced multi warehouse structure in Odoo with automated replenishment rules, stock movement tracking, real time visibility and demand forecasting logic. Priority based routing was implemented to automatically identify the most optimal warehouse for fulfilling orders based on stock availability, customer region and warehouse load. We created structured workflows for inter warehouse transfers including automated approvals, barcode based verification and instant stock updates. Serial and batch tracking were deeply integrated across operations ensuring complete traceability from vendors to customers. Orbiixa also implemented barcode based picking, packing and dispatch workflows enabling warehouse staff to manage tasks through handheld scanners with higher speed and zero manual errors. Automated purchase suggestions were added based on minimum stock thresholds, sales trends and supplier lead times. The entire ecosystem was further connected with Odoo Accounting and Sales modules to ensure synchronized data across the entire supply chain.

Result

After implementing the Odoo Multi Warehouse Management System, the client witnessed a significant transformation in their supply chain efficiency. Real time stock visibility eliminated stock discrepancies and improved accuracy by more than ninety eight percent. Order fulfillment speed increased due to automated routing and prioritized warehouse selection. Over stocking and under stocking issues drastically reduced thanks to intelligent forecasting and automated procurement recommendations. Warehouse operations became faster because barcode based workflows removed manual errors and streamlined tasks. Serial and batch tracking improved warranty claims and vendor communication enabling the client to operate with complete traceability. Management gained access to deeply informative analytics supporting strategic decision making and long term planning. The company saved a substantial amount annually by reducing wastage, optimizing stock allocation and improving procurement cycles. Overall the organization achieved a world class supply chain standard powered entirely by Odoo and engineered by Orbiixa to handle global scale operations without complexity.

Our Clients Recognize Us as the Leading Odoo Development Experts.

We transform your business vision into success using advanced Odoo solutions, creativity, and accuracy, making us the preferred partner for global enterprises.