Simplifying Supply Chain Management with Odoo

Supply chain management in 2025 demands accuracy, speed, real time collaboration, and flexible technology. Businesses can no longer depend on fragmented tools or manual tracking to manage procurement, inventory, logistics, and order fulfillment. Odoo simplifies the entire supply chain journey through its integrated ecosystem, advanced automation, and scalable modules that deliver complete visibility across operations. From multi warehouse coordination to predictive demand planning, Odoo transforms traditional supply chain processes into intelligent, data driven, and fully streamlined workflows. This blog explores how Odoo empowers businesses to simplify supply chain operations and achieve higher efficiency, profitability, and agility.

Introduction

In a rapidly evolving global market, companies must adapt to increasing customer expectations, fluctuating demand patterns, and rising logistics complexities. Supply chain excellence is no longer optional it is the backbone of business success. Odoo offers a modern ERP driven supply chain framework that integrates procurement, inventory, sales, manufacturing, accounting, quality control, and logistics into one unified platform. By eliminating operational silos and offering real time dashboards, Odoo helps organizations optimize every process from purchase to delivery while reducing costs and improving service levels.

What is It or Brief ?

Odoo Supply Chain Management is a complete suite of interconnected business modules designed to manage the end to end logistics lifecycle. It covers procurement, vendor management, stock movements, warehouse operations, demand planning, manufacturing workflows, shipping, and returns. Unlike traditional ERP systems, Odoo provides a flexible modular architecture, user friendly interface, and real time analytics that allow organizations to scale effortlessly. Whether a company manages a single warehouse or a global distribution network, Odoo ensures smooth, automated, and error free supply chain operations.

Core Technology

-

Modular ERP architecture enabling seamless integration

-

Real time database and automation engine for live updates

-

Advanced forecasting algorithms for demand planning

-

Barcode scanning and IoT device compatibility

-

Double entry inventory system for accuracy

-

API and multi system integration capabilities

-

Cloud hosting and mobile accessibility

-

Smart routing and batch picking algorithms

-

Role based access control and security layers

Uses of Technology

-

Automated purchase order creation based on stock rules

-

Real time inventory tracking across all warehouses

-

Barcode and QR code based stock operations

-

Smart batch picking and efficient warehouse routing

-

Vendor price lists and automated reordering

-

Demand forecasting and planning for optimal stock levels

-

Complete traceability through lot and serial numbers

-

Integration with shipping carriers for fast dispatch

-

Manufacturing planning with bill of materials and work orders

-

Automated invoicing and financial reconciliation

Benefits

-

Complete visibility across procurement, stock, and logistics

-

Reduction in manual work and operational errors

-

Faster order fulfillment with improved accuracy

-

Lower inventory carrying costs through smart forecasting

-

Enhanced collaboration between teams and departments

-

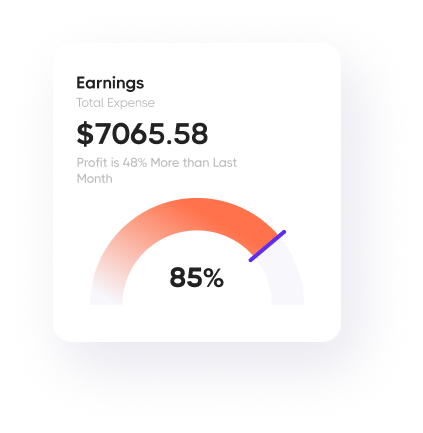

Increased profitability through optimized resource usage

-

Improved customer satisfaction with timely deliveries

-

High scalability to support multi warehouse and global operations

-

Real time reports for faster decision making

-

Seamless integration with accounting, CRM, and manufacturing

Implementation and Challenges

-

Requirement analysis to map existing workflows

-

Data migration ensuring accuracy in historical records

-

System configuration for warehouses, routes, and rules

-

User training for smooth adoption across teams

-

Integration with external logistics, ecommerce, and POS

-

Customization to align with industry specific needs

-

Change management challenges during digitization

-

Ensuring reliable network connectivity for mobile operations

-

Managing multi warehouse complexities and routing rules

-

Continuous maintenance and updates for performance optimization

Conclusion

Odoo has become a powerful engine for simplifying modern supply chain management by combining automation, integration, and real time intelligence. Companies using Odoo experience greater control over inventory, faster procurement cycles, improved warehouse efficiency, and better customer service. As the demand for digital transformation accelerates, Odoo stands as a flexible, scalable, and cost effective solution for businesses aiming to strengthen their supply chain operations. By adopting Odoo, organizations can unlock operational excellence, reduce costs, and create a future ready supply chain ecosystem.

Our Clients Recognize Us as the Leading Odoo Development Experts.

We transform your business vision into success using advanced Odoo solutions, creativity, and accuracy, making us the preferred partner for global enterprises.